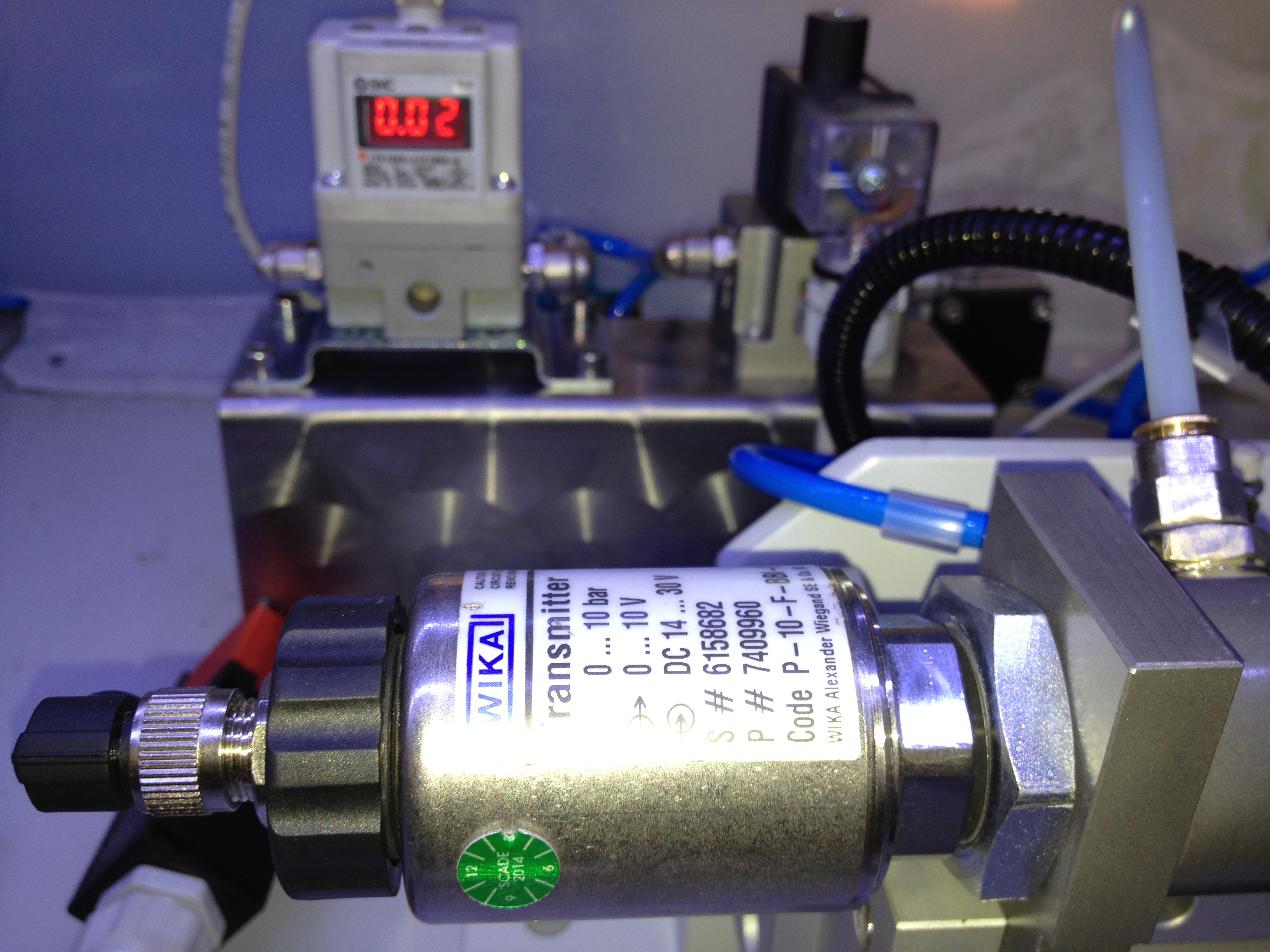

Valve pressure control line

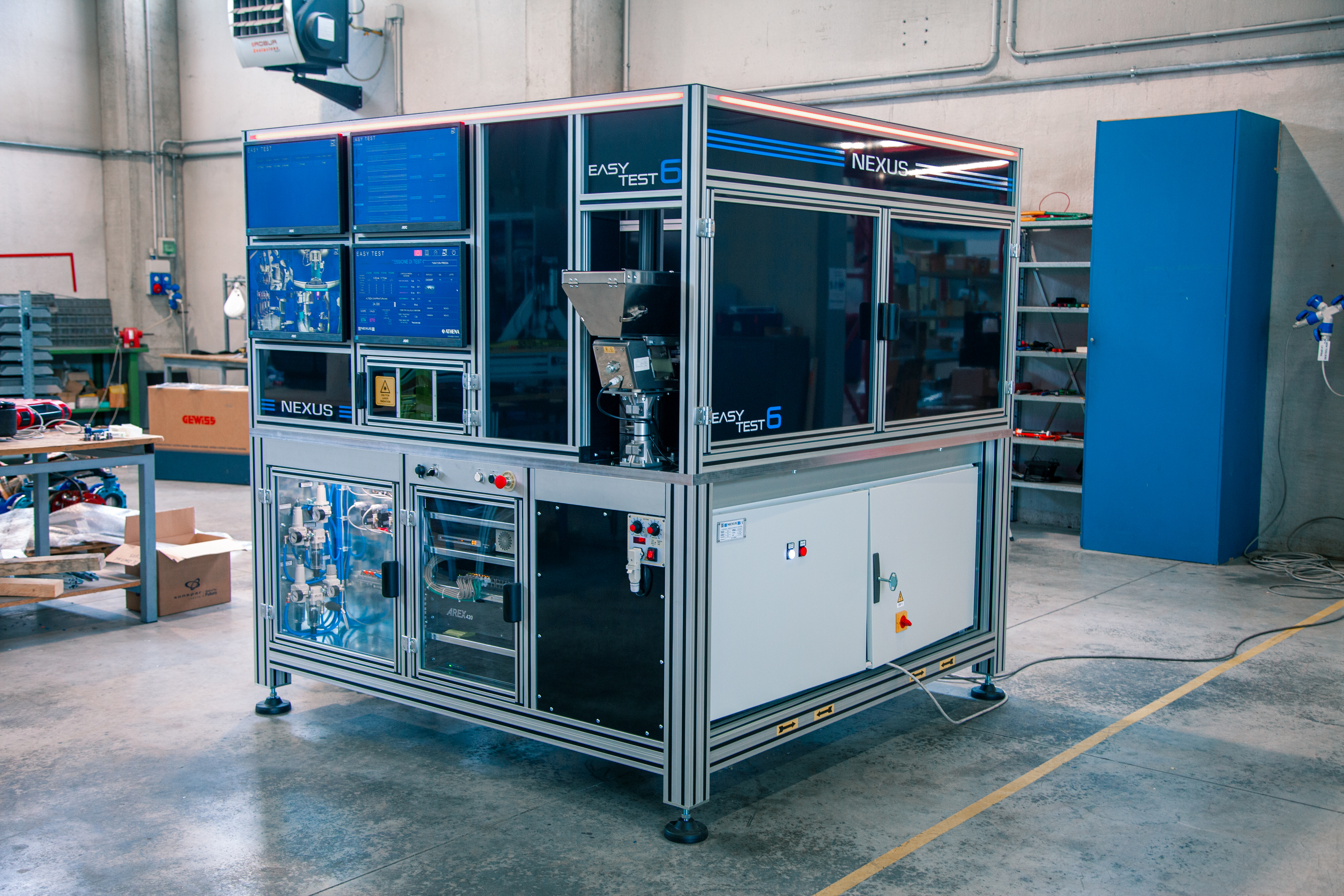

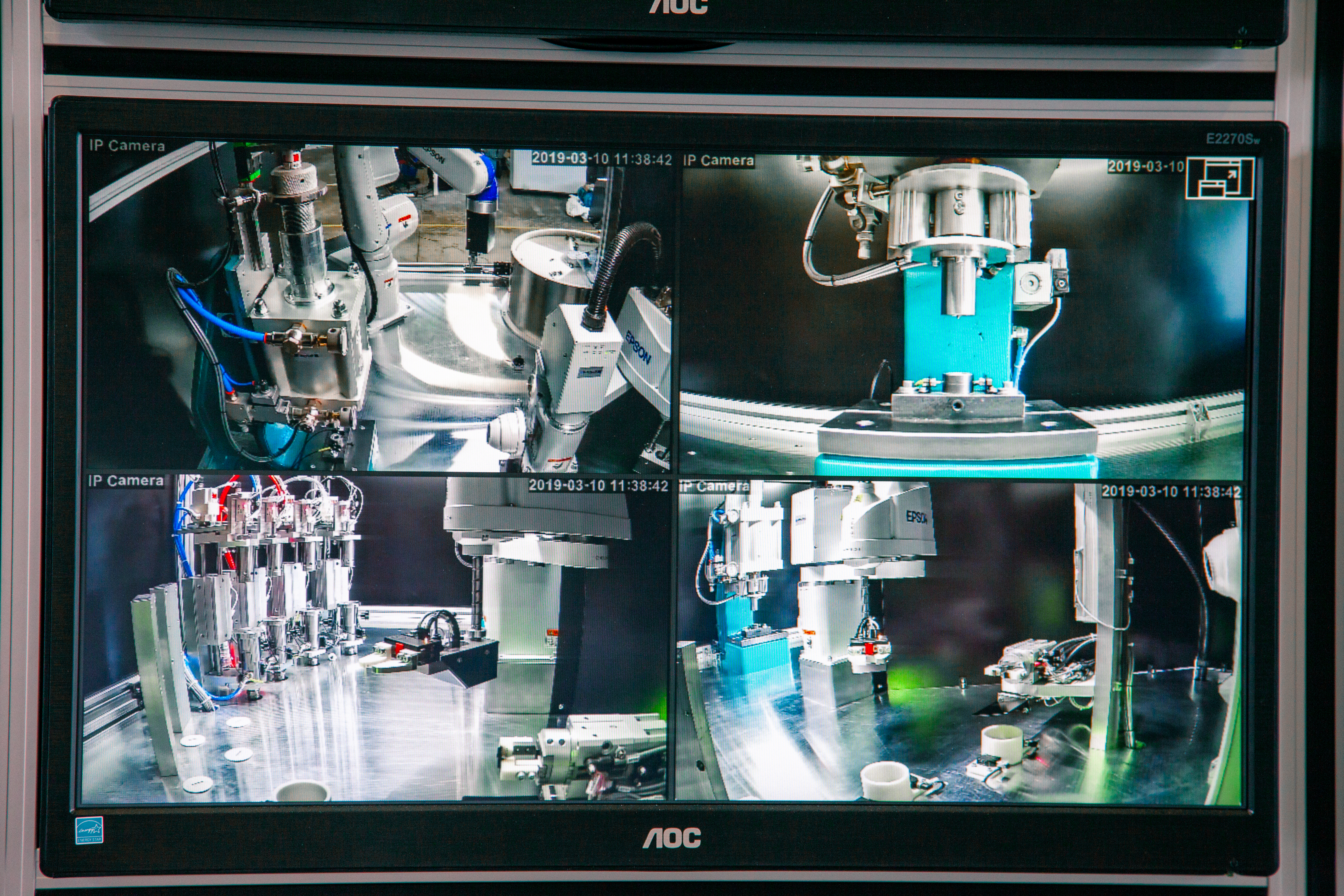

This is an example of how safety valves for gas can be controlled using stations. Initially, automation was used as a manual station to verify safety valves for LPG gas. As per customer requirements, the number of stations has increased, and the process is now completely automated.

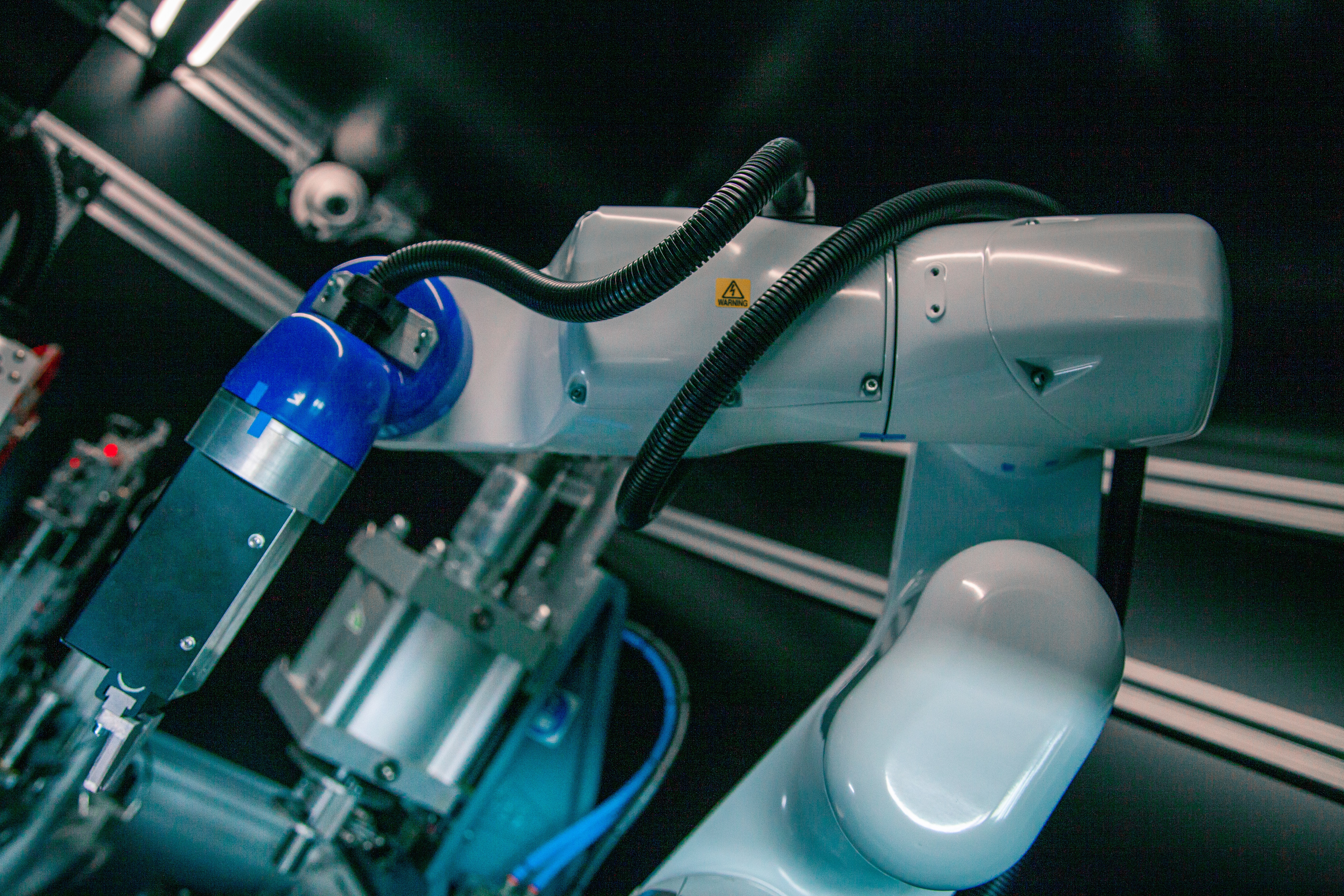

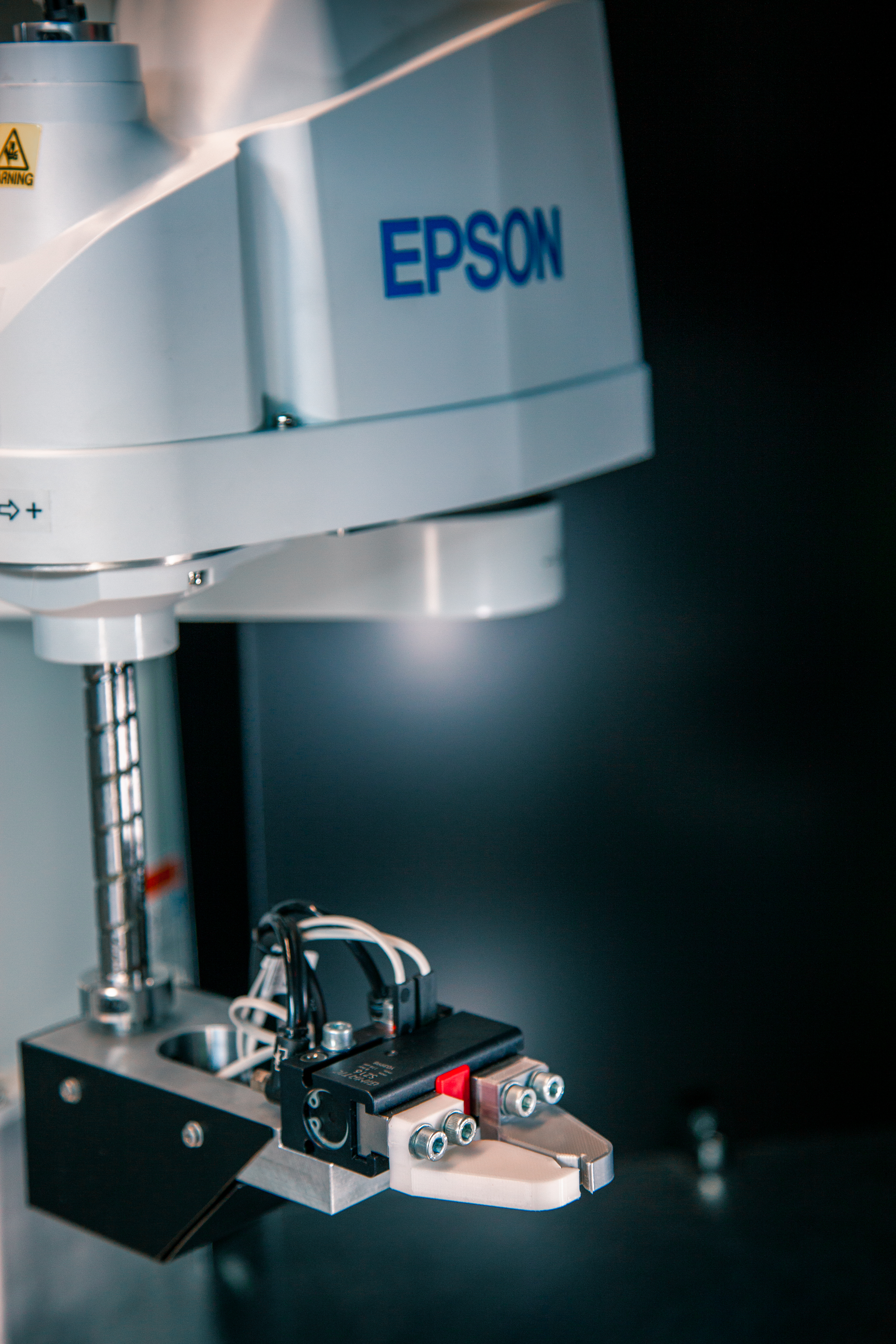

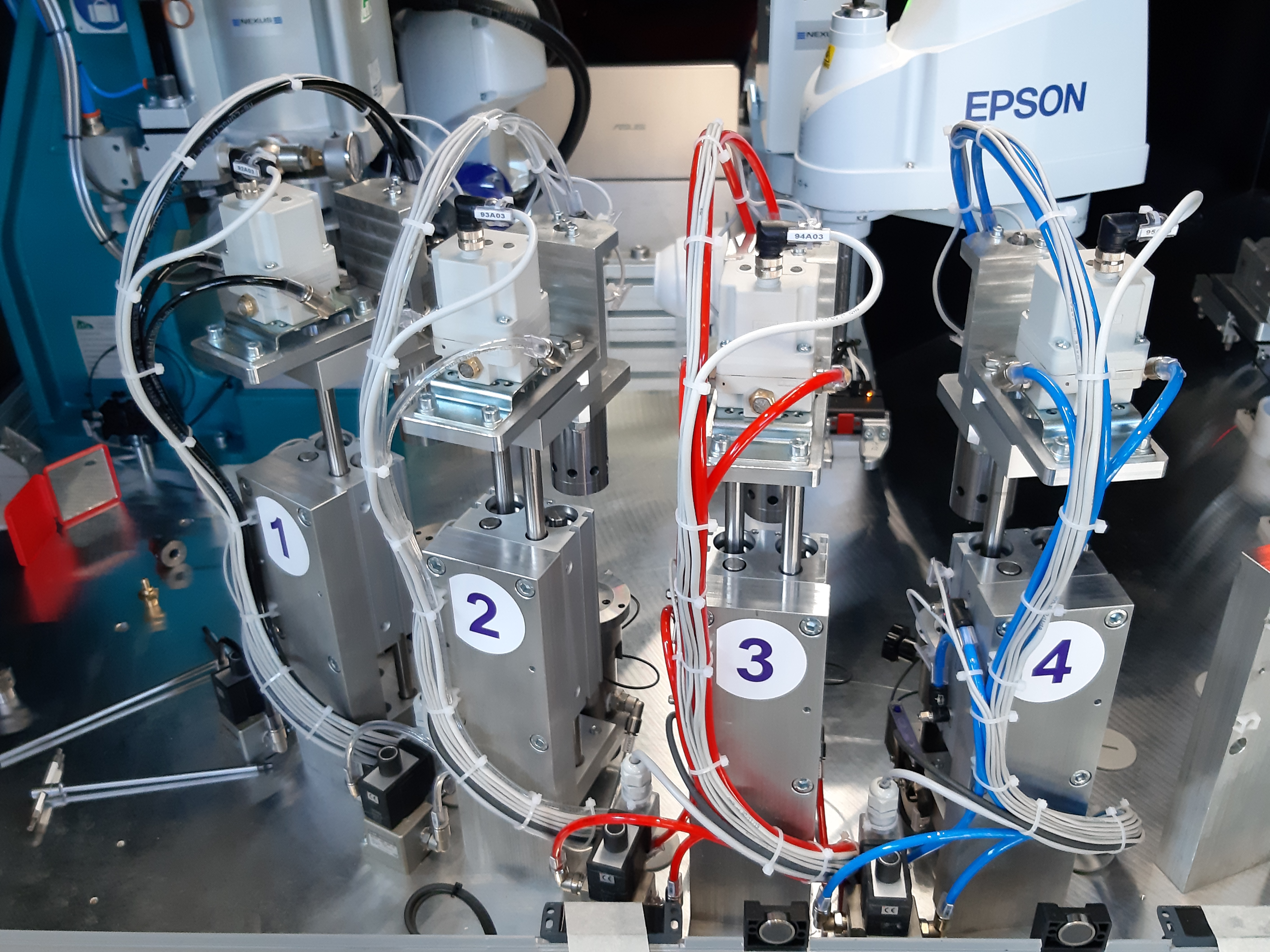

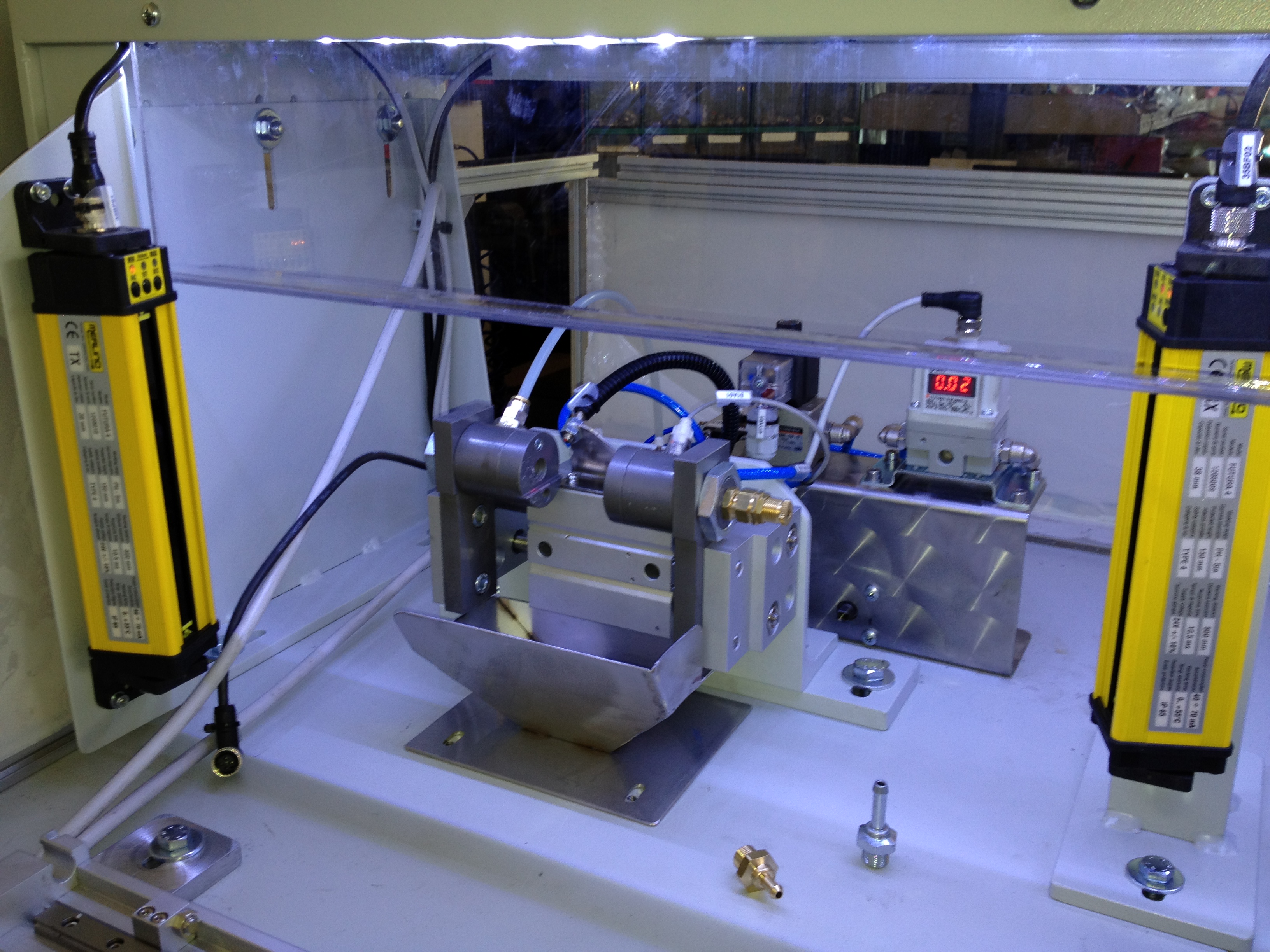

The valves are loaded onto a vice and subjected to pressure and flow tests. Based on the test results, the valve is sorted accordingly. As the customer works in the automotive sector, some valves are selected for manual verification to ensure correct functioning of the machine as well as internal diagnostics.

All production data is saved in a report, which can be accessed by the management system for complete traceability.